Soldering Iron Tips Wear Out

All tips eventually wear out due to heat and normal use.

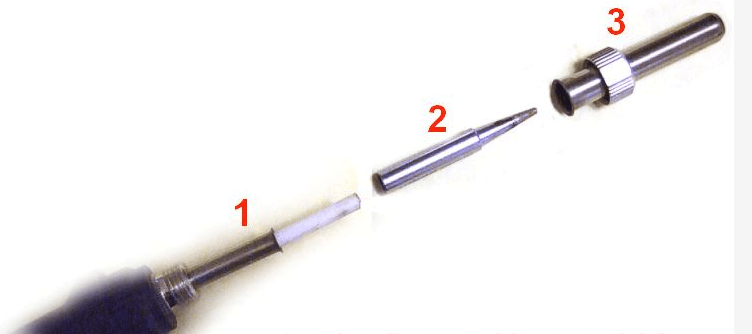

Soldering iron tips wear out. First theres the one commonly known as a b-series tip. Soldering Iron tips do not last forever. Soldering iron tips are crucial for the soldering process.

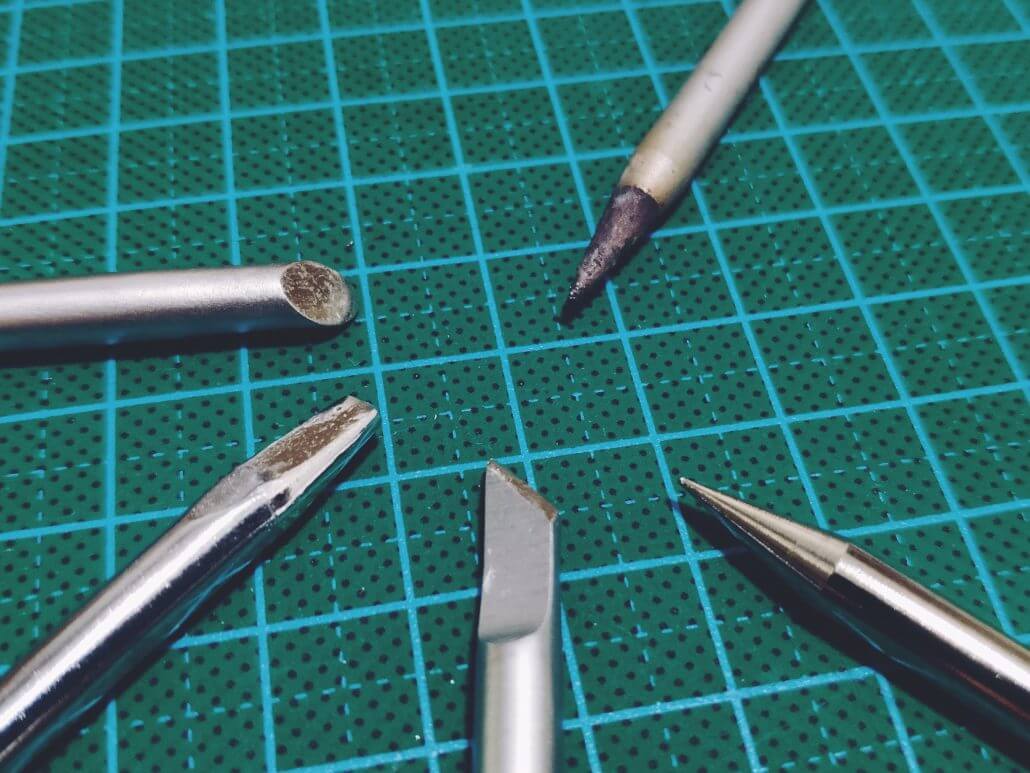

The knife soldering iron tip comes with a slanted tip resembling the shape of a knife. It is not impossible to do point soldering with this tip but it is considerably difficult as compared to the other tips. Bevel or C-series Tips.

Tips can wear out too - I had an old Radio Shack soldering iron and used it for years and even took a file to the tip to abrade off the bad and carbonized surface but it was very old and worn out. Eventually they wear out. Common signs that the tip needs replacing are.

Soldering iron tips wear out over time and unfortunately if your tool fails to transfer heat to the connection point effectively then it must be deemed unreliable and ultimately expendable. Its inevitable for soldering tips to wear out over time and need replacing. Tip tinner is available to extend the life of an oxidized tip.

Soldering tips may wear out prematurely especially if you dont know how to use it properly. Experienced operators are also likely to experience wear and tear too. The oxidation process occurs when metal is left in an oxygen-rich atmosphere.

Once the plating gets even a pin hole in it the molten tin will eat out the copper core of the tip. Protecting your solder tips can start as early as from the beginning of a solder tips lifetime. Common signs that the tip needs replacing are.