How To Fix Oxidized Solder Tip

How to use the temperature probe for the hot air rework system NoC1541 THERMOMETER SOLDERING TESTER.

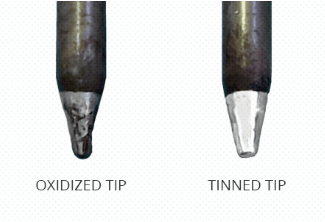

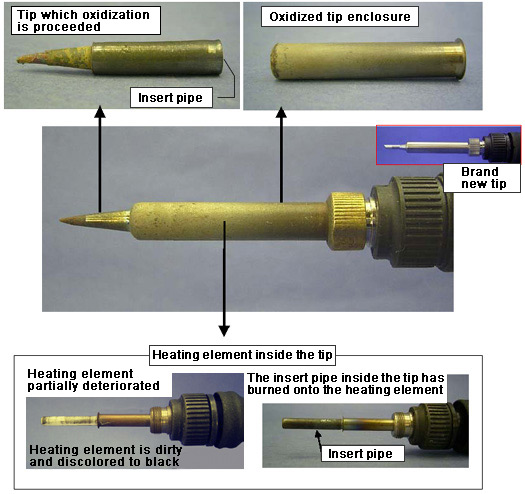

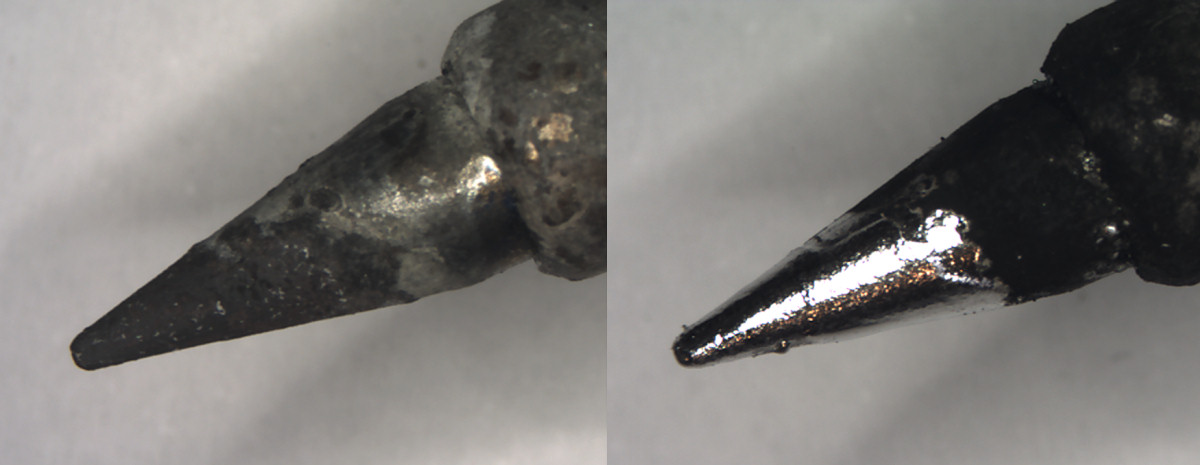

How to fix oxidized solder tip. The main motive is to remove old flux or Solder. It just drips off. The tip smokes and melts into the block and you should apply solder to tip at this point.

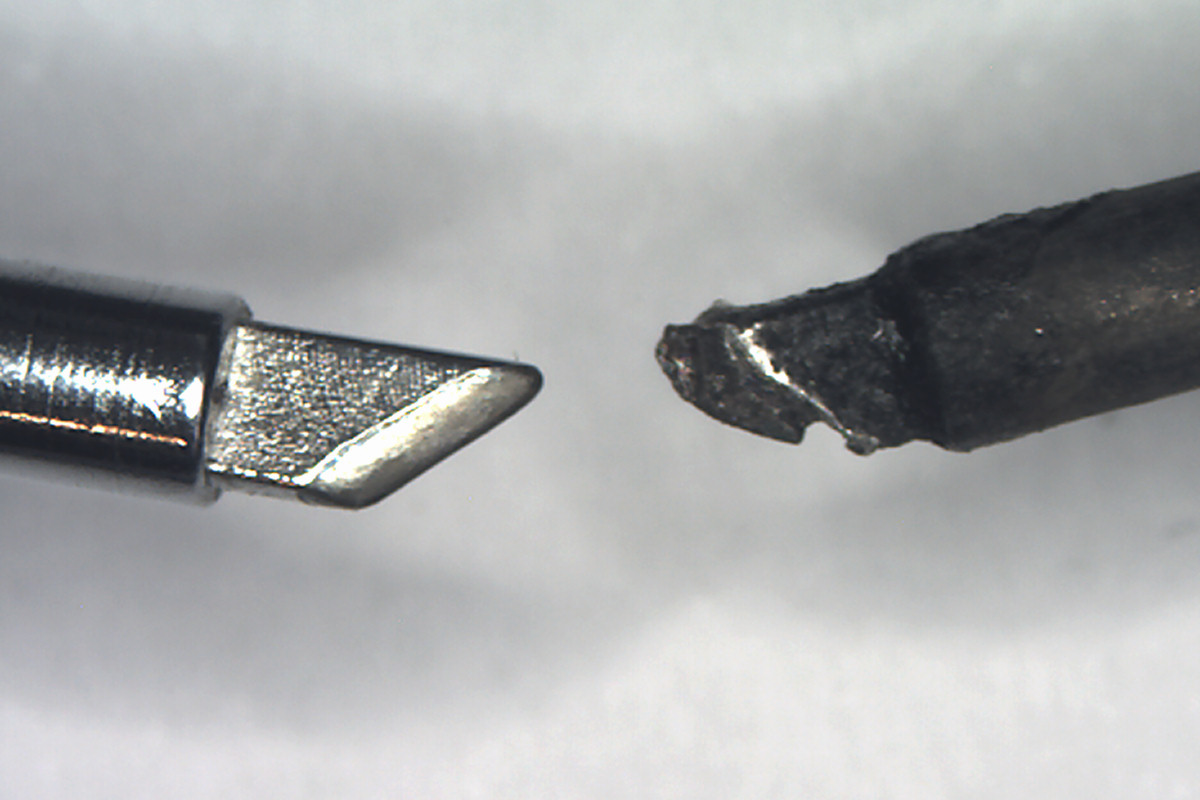

It took a lot of effort with tip tinnercleaning compound to make the solder wet the tip again. Sharp till it gives you a shiny look. Be careful not to get a thermal shock while doing this.

Heres how to deal with oxidized tips. And move the tip after applying Solder on that unless it gives a shiny finish. Then immediately re-tin the tip with rosin core solder.

The heat will activate the flux and start the chemical reaction that will remove the oxidation. Therefore it is advisable to use the dry cleaner options to avoid shock do a faster job and increase the life of the iron tip. When you are done cleaning wet the iron tip using fresh solder to get oxidized later.

This prevents the tip from oxidizing. With the iron tip cold use a polishing bar. When solder no longer flow onto the tip or it takes too long to melt the sol.

If the tip is dirty and excessively oxidized you can also use a sal ammoniac tinning block to bring it to life. You need to rub the tip on the block while rotating it. How to clean an oxidized soldering tip - YouTube.