How To Solder Car Speaker Wire

Any serious danger of melting the voice coil solder on the other side.

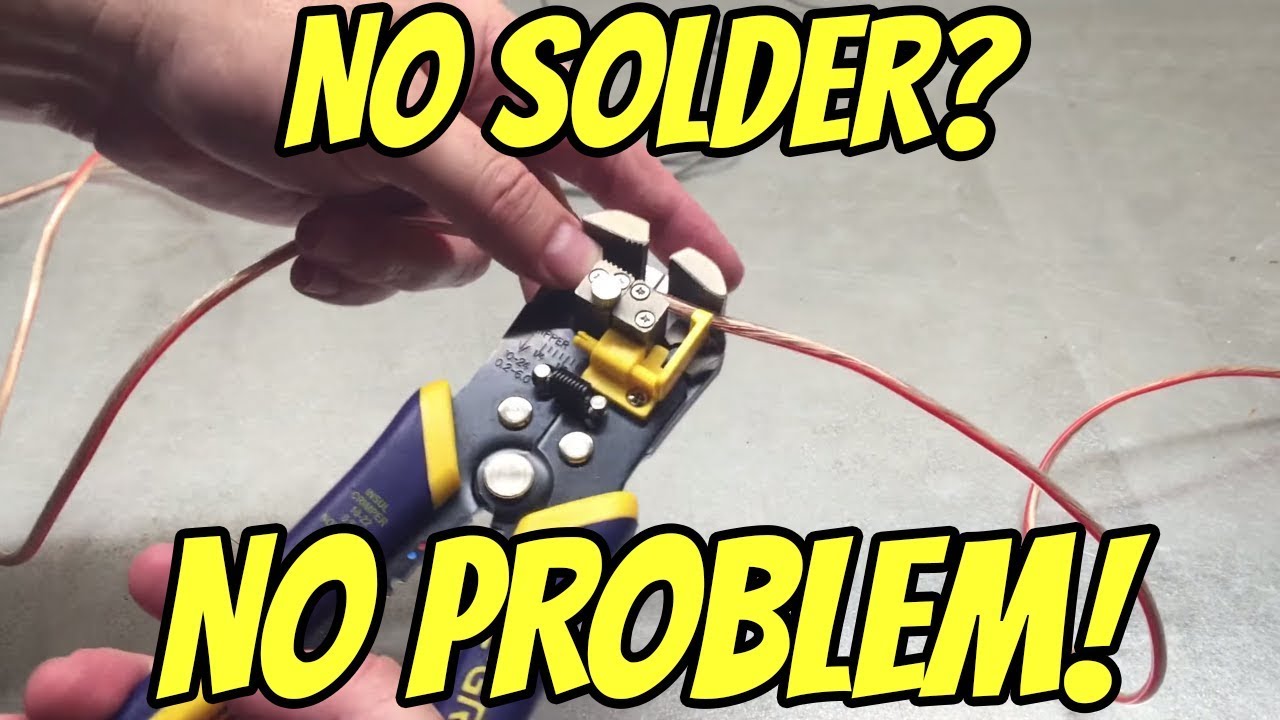

How to solder car speaker wire. Once cool remove any flux residue with a damp rag. I might choose to SOLDER the wires from the jack to the speaker terminals as opposed to using a clip-on crimp etc. It is also necessary to ensure longevity and secure connections.

If that is not the case you should cut off the parts that is touching and test again. If black and red make red the positive lead and black the negative. Both are viable but the clip has the definite edge.

In this video tutorial viewers learn how to solder speaker lead wires. If you make Cold Solder Joints where blobs of solder are caked onto the wire this will not do a very good job and it wont be very permanent. The 2 wires that comprise speaker wire are marked differently.

Thu Jul 31 2008 550 pm. Even if you crimp the wires properly the receptacle on the speaker is the weak link this one is often tinned and after a couple push on pull off cycles will no longer make good reliable contact. Its especially important when youre working on your cars speakers and the like since easier methods can come undone so quickly.

The solder if it is properly heated should melt into a liquid and flow like water over the solder joint. Step 4 - Solder the Positive Connection. Doing so will result in an ineffective joint.

One may be black and the other red or one may have a stripe down the middle of the wire while the other is blank. A clip can be easliy realigned with a pair of needlenose and and cleaned with some steel wool. Next is the quality of the solder joint.