How To Improve My Stick Welding

And if you cant find anything tack somthing up.

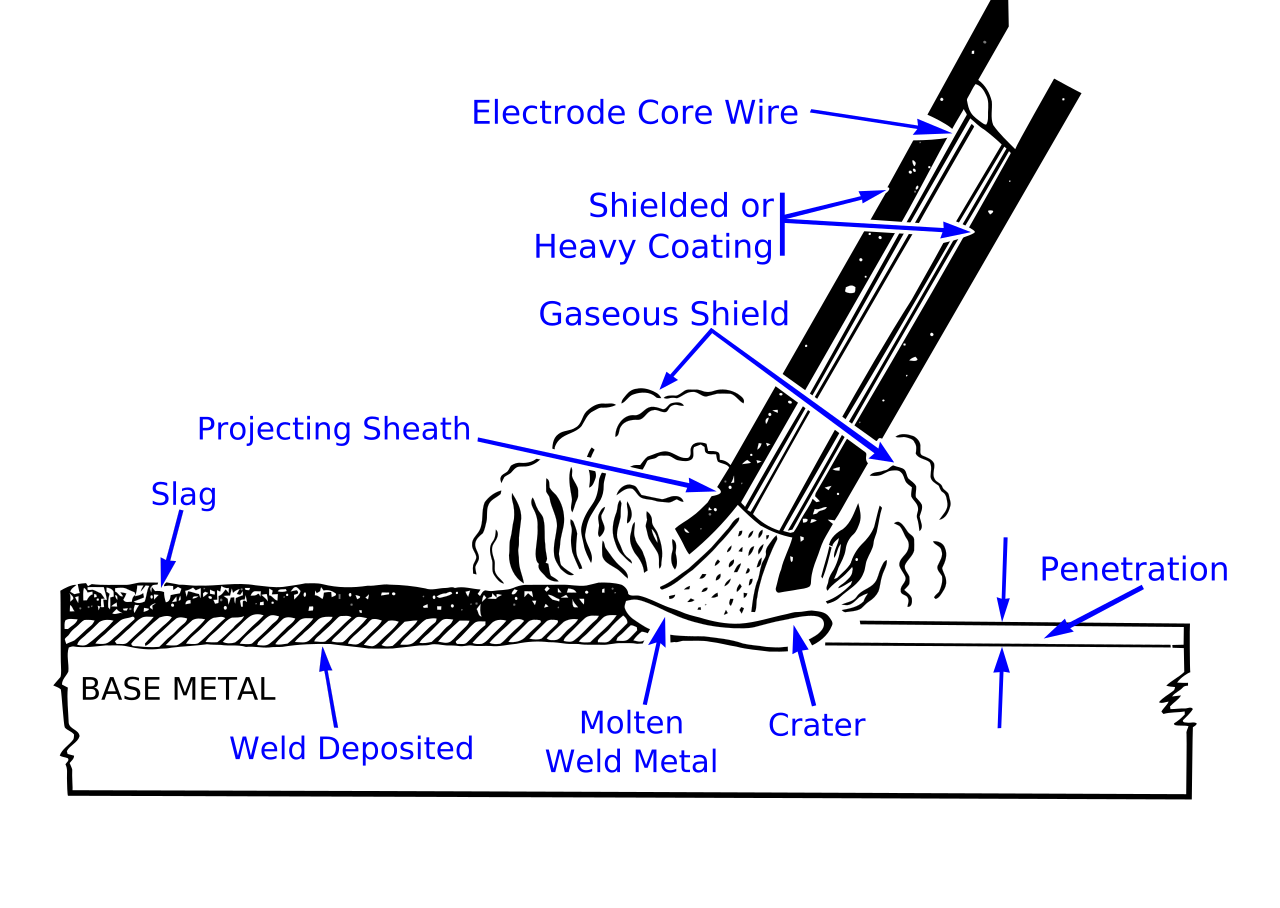

How to improve my stick welding. The following pages will help the inexperienced welder to understand welding and develop his skill. Remove the welding stinger from the electrode as fast as you can turn off the welder and break off the rod from the metal. Current setting length of the arc angle of electrodemanipulation of electrode and speed of travel.

If youre just learning the stick process technically called shielded metal arc welding SMAW remembering these five points will improve your welding technique. Often due to incorrect welding current. Because DCEN concentrates a large proportion of heat in the base plate itself your HAZ area becomes wider.

LEARNING TO STICK WELD LEARNING TO STICK WELD No one can learn to weld simply by reading about it. When you pull you can see the puddle but its hard to see where you are going because the nozzle blocks your view. Based on the app.

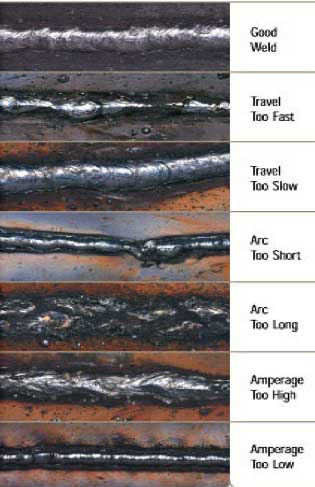

Weld splatter is not a good look mostly you will get weld splatter during arc or stick welding and even with the best MIG welders. To increase bead size use slower travel speed and a short arc technique or weld 5 degrees uphill. Always continue welding while the plate is hot Rigid parts are more prone to cracking.

Flat or 1G you drag the rod between 10 to 30 degrees in the direction of your movement. HAZ or Heat Affected Zone. I would start around 125 amps and make a test weld.

13 Surefire Ways to Improve Your Stick Welding Skills 1Be able to clearly see what you are welding If you are using a welding mask or helmet with dirty or scratched lenses it is probably time to replace them. For more detailed information order a copy of Ne Le i Ac Weldig available from the James F. Use a wire brush or grinder to remove dirt grime or rust from the area to be welded.