How To Solder Small Electrical Wires

I apply the soldering iron tip and the solder to the metal tag near to where the tinned sleeve wire touches it and gradually introduce more solder until the molten blob touches the cable and melts.

How to solder small electrical wires. After all you cant exactly use super glue instead of solder to join a wire. What do you do if you dont have access to solder or soldering equipment though. How to Solder Two Small Wires - YouTube.

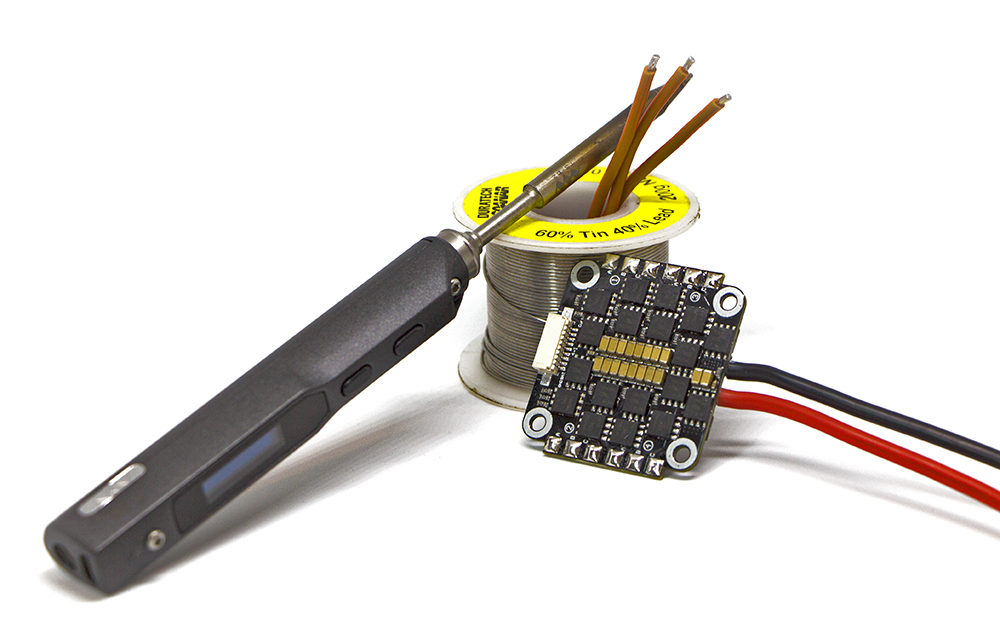

If youre using a new soldering iron you have to tin the tip. To do this heat up the soldering iron and touch the solder to the tip of the iron so that you cover the tip in a thin layer of solder. Sold in the electronics department.

Soldering small wires to very small connections such as unused pins on QFPs First tin the connection point. Solder is commonly used to attach wires and other electrical components by melting a small amount of conductive material to secure the connection. Wipe the excess off with a damp paper towel or sponge.

Meets The EU RoHS Directive 201165EU Claim. Ad Low-Price High-Quality electronic Connectors Ready to Ship. Ad Quality Solder Wire Drawing Machine.

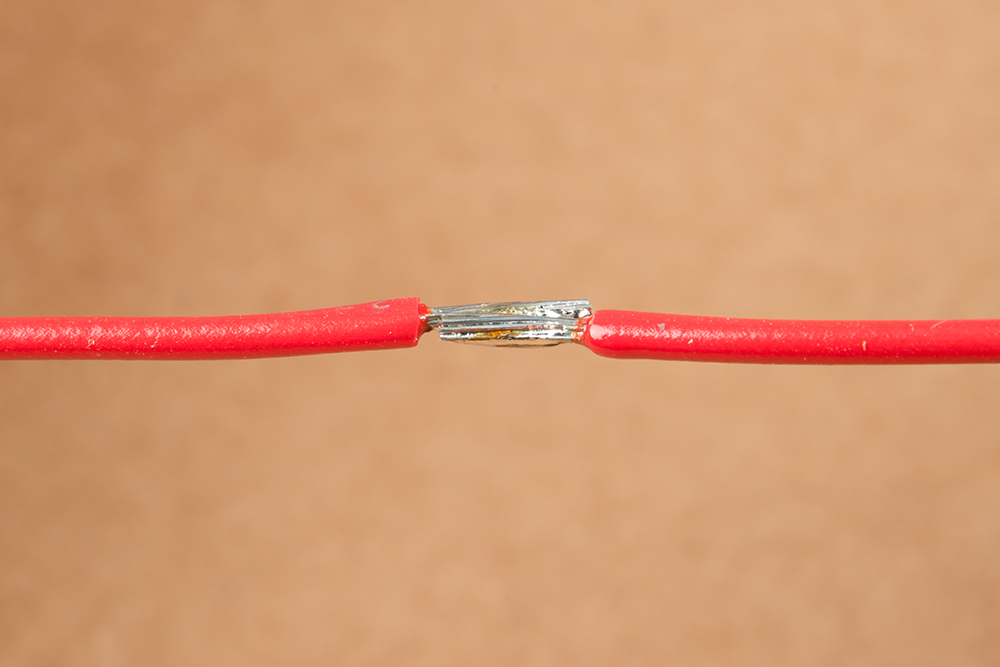

With a drop of solder on the iron you hold the wire in the drop and add a bit of resin core electronics solder and the wire will take the solder if a few moments. Remove the soldering iron and wait a few seconds to let the soldered connection cool and harden. Pinch the wire tip between the solder and the iron tip to tin and flow the wire end.

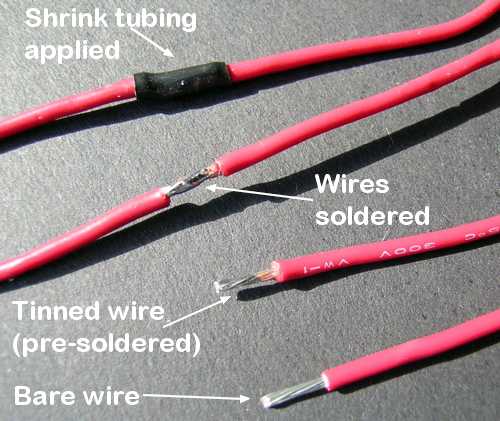

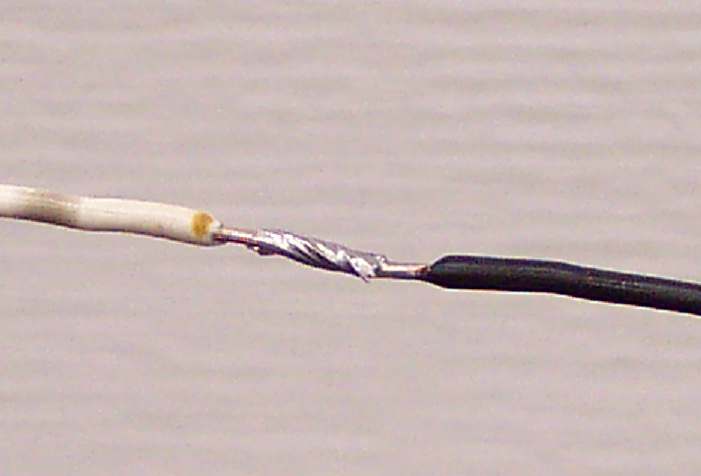

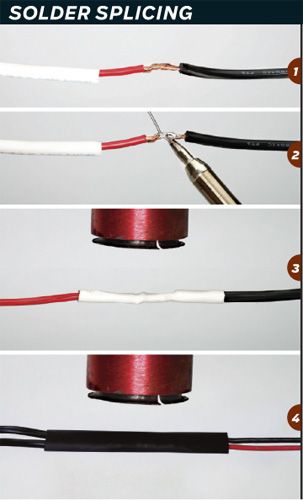

Always use rosin-core solder. Install the shrink wrap first solder the wires then slide the wrap to cover the solder shrink the wrap with a flame careful the wrap can shrink too much and split open then you will need to start over. Automotive wiring should be soldered and protected properly in order to withstand all types of weather rain snow and salt.

/close-up-man-hands-soldering-audio-cable-with-xlr-connector-1078041206-472dd1f03b084f2b9ab373c9dff8080e.jpg)