How To Solder Fine Electrical Wires

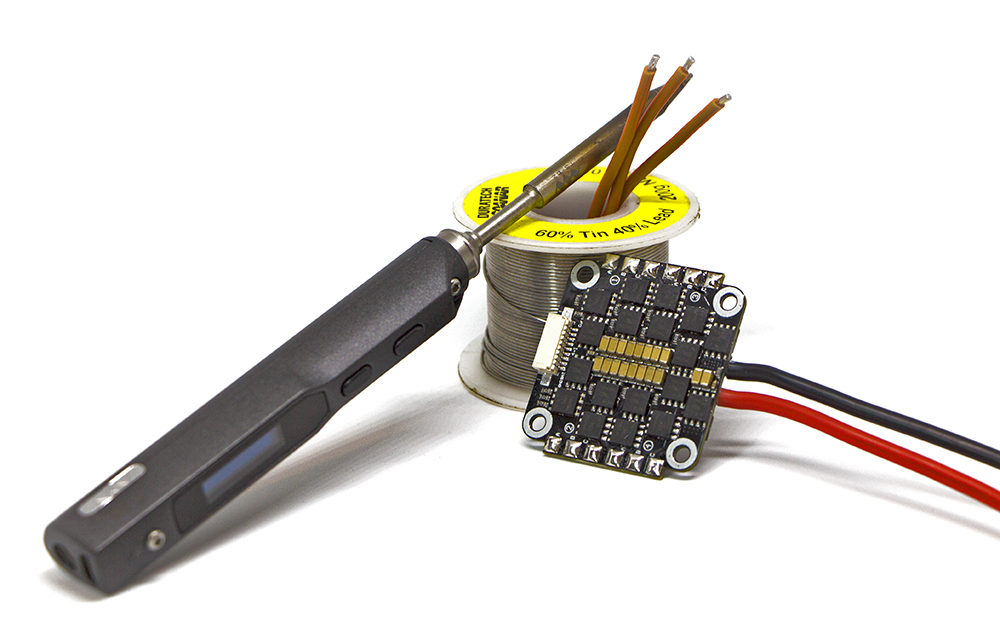

You need to apply the heat to the metal part on the plug because that takes the longest to heat and melt the solder.

How to solder fine electrical wires. The solder should flow freely into the wire and coat it. With a drop of solder on the iron you hold the wire in the drop and add a bit of resin core electronics solder and the wire will take the solder if a few moments. If you have a solder pot then soldering through enamel wire can be.

Make sure your soldering iron is fully heated and touch the tip to the end of one of the wires. Tin the wire end before soldering to make sure you have most of the insulation removed. Do not put the solder on the iron tip as the tip will be hotter than the wire and the solder may not flow into the wire.

The advantage of solder is that. Then twist the filaments of each wire tightly to make them orderly. Dodgy wiring inadequate fusing and exposed connectors could lead to a fire.

How to Solder Two Small Wires - YouTube. When you are tinning the wires the resin will help the solder flow smoothly. Heat the end of the wire to burn the insulating material and sand carefully with fine 400 grit sandpaper by folding it with the grit inside and running the wire end through it.

Repeat this process on. How to Solder Wires Together Best tips and tricks - YouTube. If that is enammelled wire as it appears then as others have said the best method of stripping is to heat the ends with a flame to destroy the insulation and scrape off the residue.

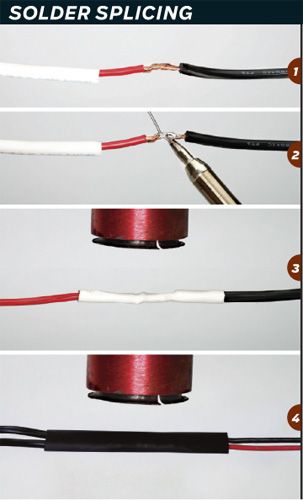

There is one way to twist wires together for soldering- a horizontal twist that yields a continues length of. Tinning the tips of stranded wires holds the fine wires together and makes it easy to connect them to screw terminals or other connectors. When soldering it is always a good idea to disconnect the wires from the electronics whenever possible as the heat can easily transfer to the electrical components.