How To Solder Copper Wires Together

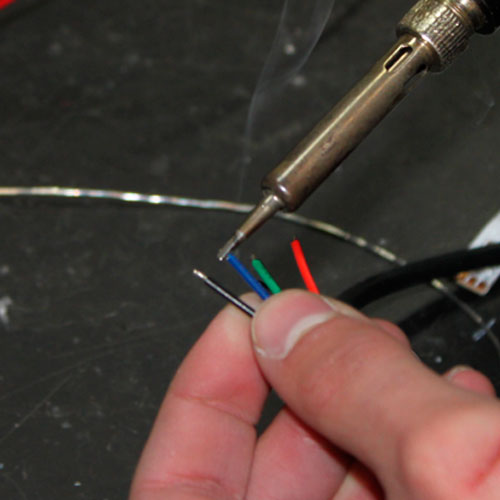

Step 3 Plug the soldering guniron into an electrical outlet and allow it to heat up for about three to five minutes.

How to solder copper wires together. Your solder will be applied opposite from the iron on top of the wire. Position the tip of the flame on the tubing and touch the tip of the solder to the joint part. In this way we will solder both tips together to strengthen the bond.

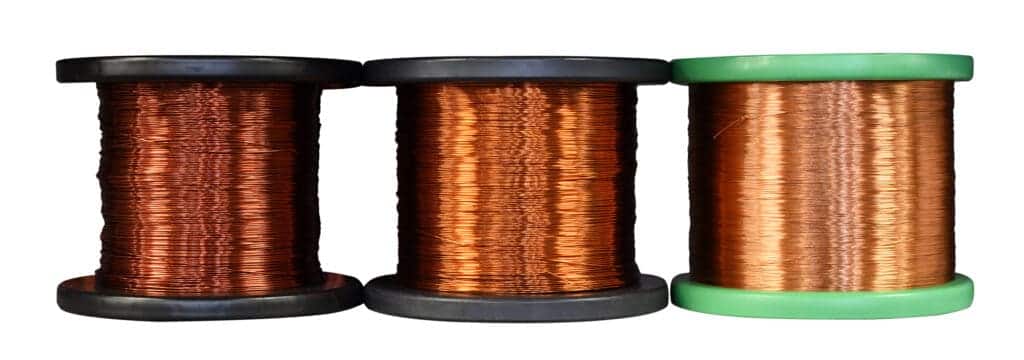

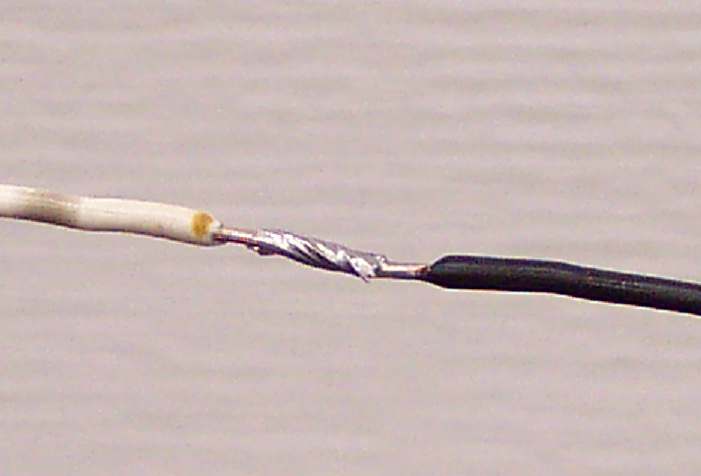

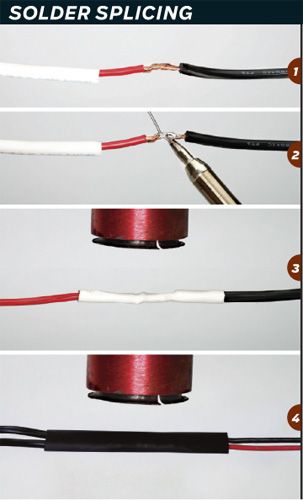

Bring both stripped ends together like shown in the image below. Begin by laying out all the items containing copper wire that you wish to solder. Your electrician would just go to every outlet and pigtail the aluminum with a short copper strand using a AlCu Wire Connector these are usually purple for identification.

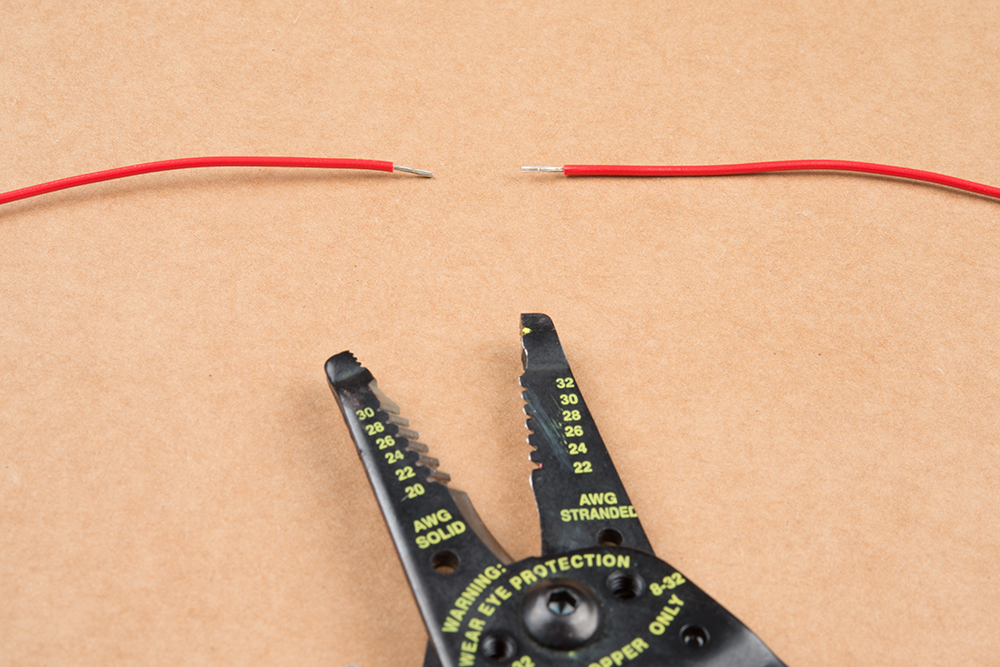

Apply the solderless copper bonding to the pipe. If the wire is stranded twist the strands together with your fingers. Do this very carefully slowly and make sure to test the melting point of the material.

Connect together stranded wire and solid wire as shown in the third picture Use a thin solid wire 28 AWG-30 AWG and wrap it around both wires. Let dry per the manufacturers instructions. Touch the solder to the pipe.

After tinning the heads of both header and wire put them together. Cut the two wires in order to make sure that the copper core of the wire is not corroded or contaminated inside see image below. Now its time to show you how to solder wires together.

For outlets you can pigtail or just connect an AlCu rated outlet. Clean and deburr your pipe and fitting as you would for regular copper pipe soldering. As the melt will start to cool down the bond will get strong.

/close-up-man-hands-soldering-audio-cable-with-xlr-connector-1078041206-472dd1f03b084f2b9ab373c9dff8080e.jpg)