How To Remove Silicon Oxide From Iron

Trihydrated iron oxide slightly soluble in aq.

How to remove silicon oxide from iron. The physical removal of rust by way of a wire brush wire wheel or grinder is a quick method of exposing raw metal in preparation for painting or welding. IronIII oxide carbon iron carbon dioxide. Therefore it is advisable to use the dry cleaner options to avoid shock do a faster job and increase the life of the iron tip.

A better wood bleach that can leach out minerals is a mixture of sodium hydroxide drain cleaner and hydrogen peroxide. Calcium oxide is used to remove silicon impurity in iron extraction. Be careful not to get a thermal shock while doing this.

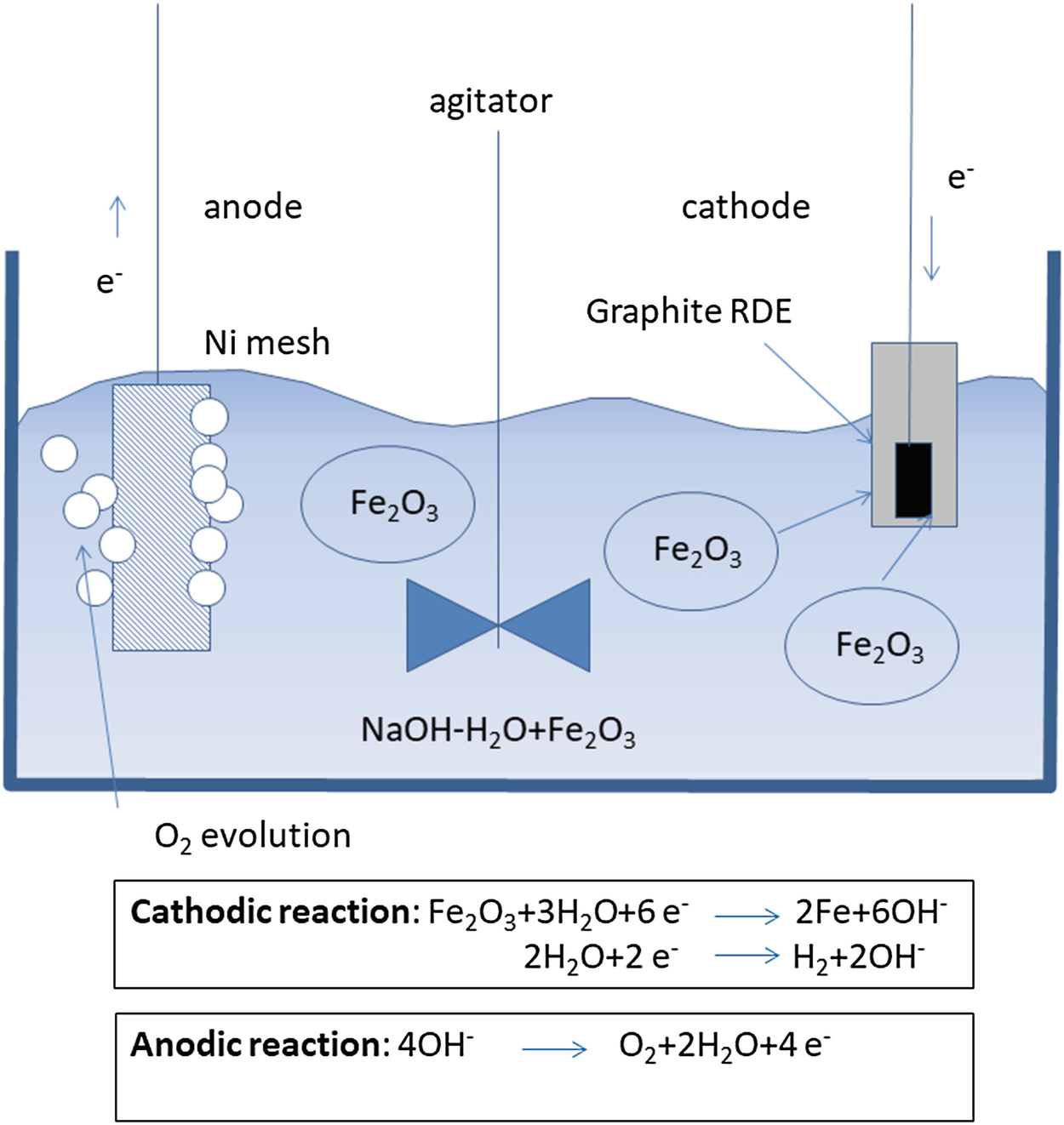

The standard procedure for attempting to remove any surface oxide involves various wet etches generally concluding with a dip in dilute HF. The pilot plant had continued to pro-duce rust for several weeks as long as it was run and the effluent was highly colored with finely divided hydrous. Silica Removal by Ferric Oxide large blasts of air at 90-psi.

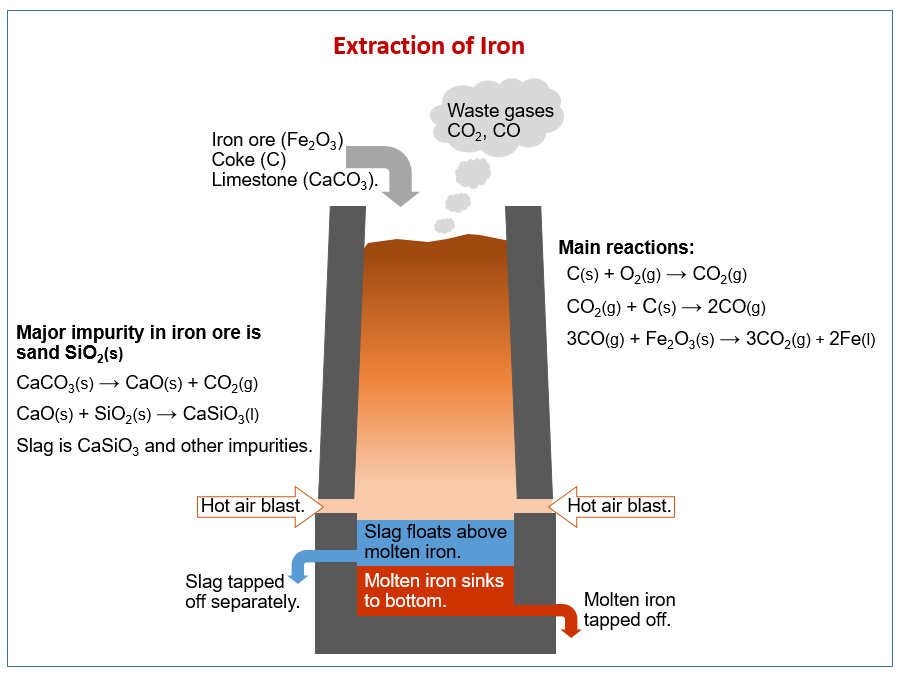

Extraction of Iron is done in many steps like oxidation combustion fusion reduction etc. Factory price biogas h2s scrubber Iron Oxide desulfurizer to remove H2S for Biogas Purification Biogas scrubberMore information please contact with us Mob. While this method has its merits it isnt necessarily ideal for all applications.

This is a first purification. This CaO later combines with silica and forms slag. You can remove oxides easier by wiping the soldering iron tip in a wet sponge.

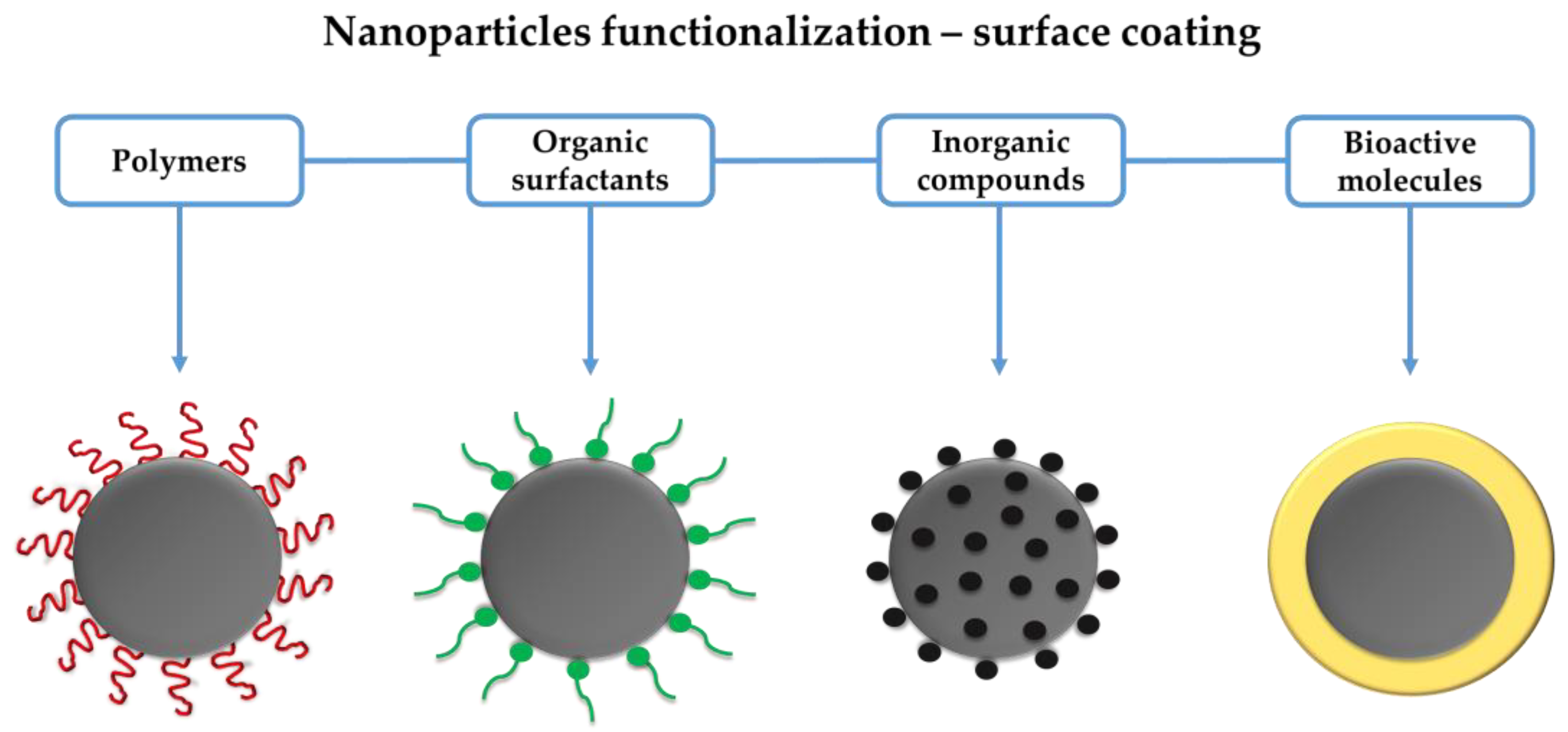

A method of removing at least a portion of a silicon oxide material is disclosed. Calcium oxide also plays an important part in the Basic Oxygen Steelmaking furnaceHere it helps to remove impurities such as phosphorus and sulphur from the steel. Calcium oxide silicon dioxide calcium silicate.