How To Prepare Soldering Flux

Removing Coating From Metal.

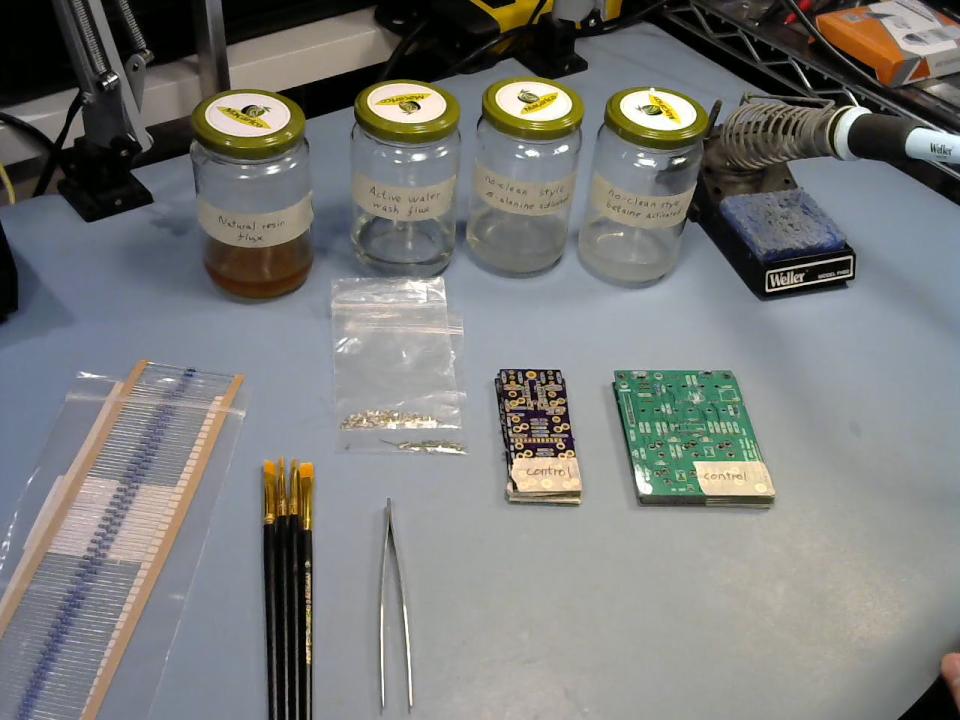

How to prepare soldering flux. Use a small paintbrush or your fingers to scoop up a small amount of soldering flux. Of baking soda with enough warm water to make a paste. Will create a barrier between the metal and the solderThink of the dirty surface like plastic wrap over your ham sandwich your potential solder join.

Step 2- Using a brush apply flux with solder to both pieces of the terminal that need to be connected. Stir the juice in the container for 10 seconds with the wooden spoon. The citric acid flux you have made can now be used to prepare metal for soldering.

The natural pine tar in the cone leaves works as a flux and can be extracted. Place the strainer in the kitchen sink for washing later. Important variables such as ambient temperature local code guidelines and any jobsite time limitations should all be considered prior to purchasing your soldering supplies.

Prepare the Metal You Want to Solder. Push the soldering gun onto a side of your wires to melt flux. Make sure the soldering iron is hot.

Start grinding down the cone against the dish in a circular motion. We try it out and then test it by soldering a 28pin SOIC chip. Before you start soldering ensure your materials and hands are clean of oils and grease.

Read the safety data sheet for borax cone here. Maintain proper angle between the two. What is Solder Flux.