How To Keep Solder Tip Clean

You should not have to do more than periodically wipe the tip clean with a damp sponge then re-tin with fresh solder.

How to keep solder tip clean. Wipe the iron on a damp sponge to remove the excess. Switch on the Soldering Station or the Iron and Make sure it is Hot Enough. Solder if you get excess solder on tip clean it.

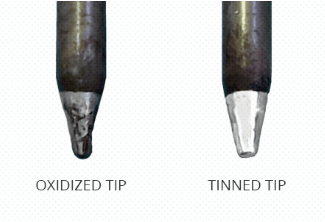

Apply liquid flux to the working area of the tip and submerse it into the molten solder in a smooth even motion. Use fluxes Spongeless and metal wool to remove small amounts of contaminants from your soldering iron tips during soldering circuit board or any other components. Clean it down to a fins shiny finish.

Its a bunch of thick tinsel-like wires intertwined. Ive been using a Hakko 936 soldering station since October now through many projects and the tip is still very intact almost as good as new. With the iron tip cold use a polishing bar.

After every soldering cycle make sure that you clean the tip with a wet sponge for long-life soldering tips or a steel wool sponge copper or iron. The Action Road - Focus 1977-1983. Turn the solder pot on and allow it to achieve the desired temperature.

Then dip into the tin of tinner cleaner with a slight twisting action. This is done by first ensuring the tip is clean and free of surface oxides. If some of the oxides are just sticking really well you could try to mildly abrade them on a brass sponge copper braid or similar but you cant be too hard or you will damage the iron plating good tips are typically copper core plated with iron then chromium everywhere but the working area.

Then immediately re-tin the tip with rosin core solder. Cover the tip immediately with solder after cleaning to prevent further oxidation. New tips require an initial seasoning which is simply.