How To Improve Soldering Process

However there are different ways one can use in order to improve the soldering skills.

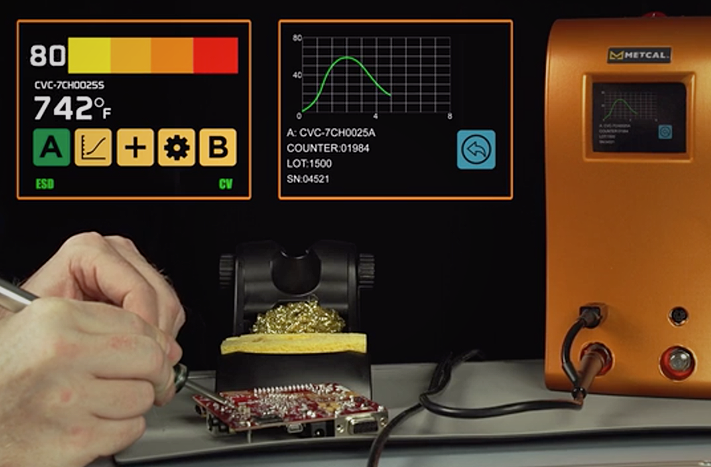

How to improve soldering process. If the soldering iron tip isnt responding to the extra solder revive dirty. This process helps to improve the heat transfer from the iron to the object to be soldered. The solder metal has a lower melting temperature than the working piece.

However tin and tinlead melt at PCB soldering temperatures and the solder merely mixes with the melted plating. The hot air heaters blow hot air over the PCBs before they pass towards the wave soldering machine. Apply mechanical structure to support the board.

Begin by making sure the tip is attached to the iron and screwed tightly in place. Never set the soldering iron down on anything other than an iron stand. Preheating of PCBs is done using hot air heaters.

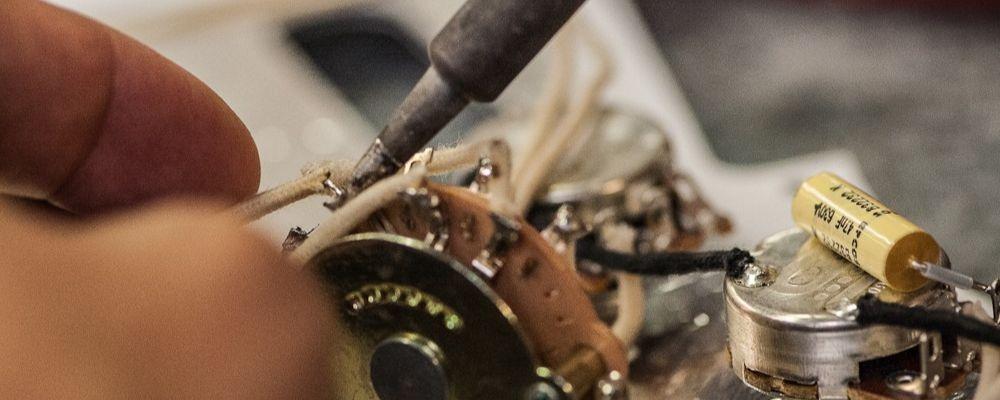

Tinning also helps protect the tip and reduce wear. The solder should flow in the opposite direction from that of the assembly. Good soldering is influenced by how clean the tip of your soldering iron is.

Once the solder flows remove the heat source immediately. A clean and tinned soldering tip conducts heat through the desoldering braid better and starts the wicking action faster. Reduce conveyor speed to increase solder contact time Increase flux volume applied reduce air knife pressure Use more active flux systems such.

Soldering is one of the best ways to fix the components to the circuit and also an important skill in mastering the guitar basics quickly. Increasing the amount of solder paste locally rather than all of the solder ball pads increases the amount of solder. After prolonged use the tip will become dirty which will make the soldering process difficult.