How To Improve My Tig Welding

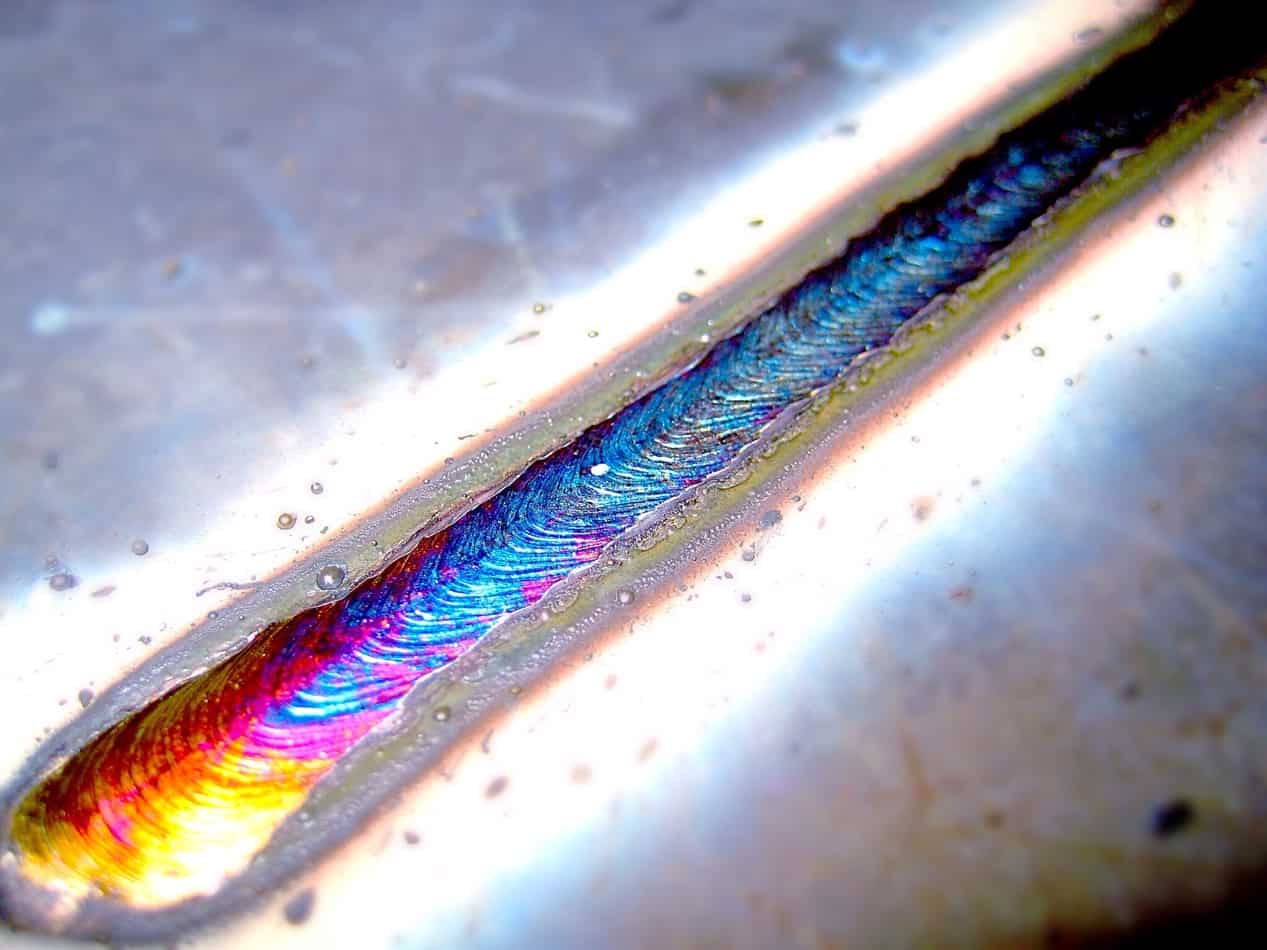

Tig welding can produce beautiful looking welds and more importantly x-ray quality deposits on some of the most critical welding applications.

How to improve my tig welding. Current is related to the depth of penetration the welding speed and the quality of the weld. S-curves or welds on round things. Inverters operate by switching high-voltage low-amperage alternating current AC into direct current DC back and forth at a very.

Some welds work better with a point while others need a rounded tip. Clean the scale off the metal before you weld it. TIG can be used to weld copper titanium even two dissimilar metals and is handy for making tricky welds eg.

After practicing autogenous welds take the next step in TIG welding by adding filler metal. It will weld another and easier. Tungsten Inert Gas welding is another type of welding that you can try out.

TIG Welding is one type of welding amongst a few choices you have - MIG Stick Oxyacetylene etc. Sharing my go to method for TIG welding up a gap. There are occasions where I rest my forearms or even my.

I learned to TIG weld by holding the torch in my right hand and moving the torch from right to left while feeding filler with my left hand. Posted by 5 minutes ago. 1 point 3 years ago.

Im 14 and just started I keep my auto-darkening helmet to go to around shade 10 in dark-state and I dont know what Im doing wrong to not be able to see the weld puddle that is present during welding. Some tips that will help you use direct current to TIG weld aluminum are. TIG welding requires proper shape for the electrode tip.