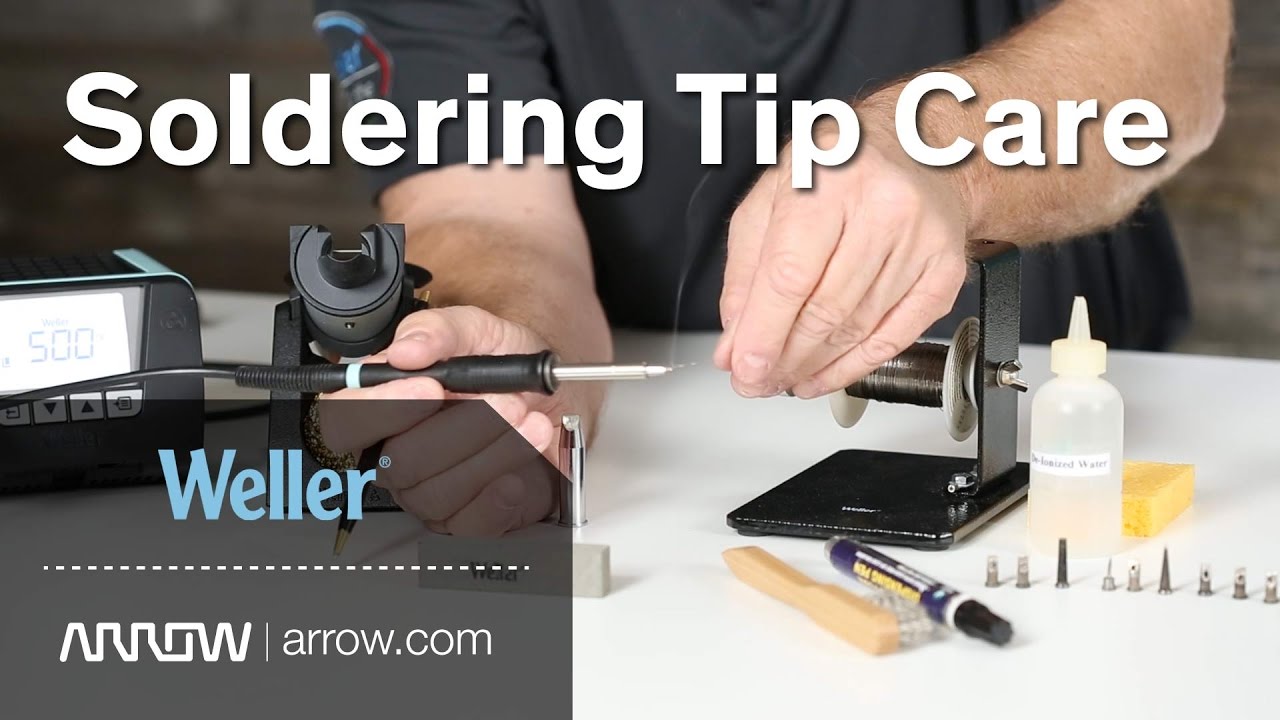

How To Clean A Weller Soldering Iron Tip

The flux in tip cleaner removes the oxidation and build up from the soldering iron tip and then the solder re-tins the tip ready for use.

How to clean a weller soldering iron tip. And if you try to de- solder anything you will damage the tip. That is very expensive for a piece of copper or brass. Melt some good quality of solder wire on the Tip.

Repeat the Process 3-4 Times until the Soldering Tips start Shining. It is hazardous so please read all safety tips included in or on the packaging. Apart from removing the flux off it is essential to clean off surplus solder.

Wire wool has the advantage of not cooling down the soldering iron too much and you dont have to wait for the iron to get its desired temperature. Wipe the iron on a damp sponge to remove the excess. Leads from the 5 conductor cord two wires to sensor two to heater ground.

Handling the iron while still hot results in severe burns. As soft as possible. I use a sponge wettened with deionized water.

Im looking forward to buy 35mm copper wire instead and got it electroplated by nickel and iron. Unplug the soldering iron and allow it to cool completely. Switch on the Soldering Station or the Iron and Make sure it is Hot Enough.

The sensor element Weller part EC229A is in a black plastic housing at. Use stainless steel wool flux and thick clothe to clean the tip. If Ill be sucessfull in outsourcing parts and services.