How To Clean A Dirty Soldering Tip

You can also clean with JBC sand.

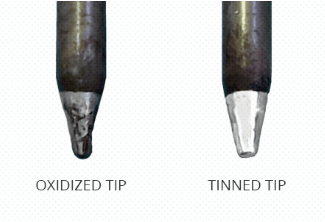

How to clean a dirty soldering tip. The tip tinner cleaner is a chemical method for cleaning and retinning the tip at the same time. This is because as the soldering iron expands and contracts quickly. If your soldering tip becomes detinned oxidized it can be restored in a number of ways.

If you choose to use a brush do it only on the solder. Flood the tip with solder after cleaning to cover the entire working surface of the tip. Then immediately re-tin the tip with rosin core solder.

Dedicated tip cleaning mesh is the best thing Ive found for that but the traditional damp sponge works fairly well. A polyurethane foam bar with embedded abrasives which is used to polish the working end of the tip to remove surface oxides. Fit the new tip into the retaining sleeve and screw it back to the heating element.

Wipe off the irons tip between strokes. You also can clean your soldering iron tip with a sponge while using it to keep it clean. Then slide the retaining nut over the tip and sleeve and tighten it using your hands.

Use only distilled or deionized water for cleaning sponges Use commercial tip tinners Use regular tap water on the cleaning sponge Use dirty or contaminated sponges Drop or hit the tip against hard. In this case you have to damp down the steel wool and rub the metal tip of the soldering iron and as a result it will remove the rust and stains. This method is advisable as a last resort.

Cleaning and maintaining soldering tips ensure its longer life. Its something of a vi-vs-emacs war about which is better but whatever. To use the Tip tinnercleaner heat the soldering iron.